CNC (Computer Numerical Control) edging involves the use of computer-controlled machinery to shape and finish the edges of glass panels with exceptional precision. Unlike traditional methods that rely on manual labor, CNC edging ensures consistent results, reduces errors, and allows for intricate designs and complex geometries.

Advantages of CNC Edging:

1. Precision and Accuracy:

CNC edging eliminates the variability associated with manual processes, delivering a level of precision that is crucial in various industries. Whether it’s architectural glass, automotive applications, or electronic displays, CNC-edged glass meets the stringent standards demanded by modern design and manufacturing.

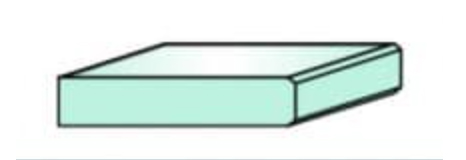

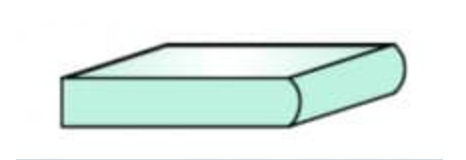

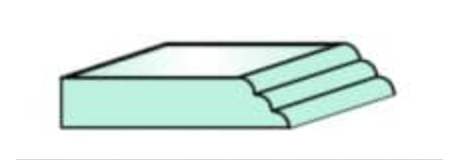

2. Customization and Intricate Designs:

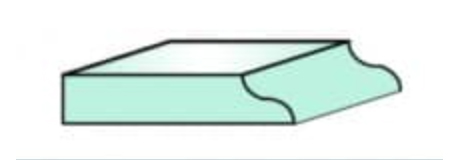

One of the key advantages of CNC edging is its ability to create intricate edge profiles and custom designs. Architects and designers can unleash their creativity, knowing that CNC machines can execute complex shapes and patterns with utmost accuracy. This has opened up new possibilities for unique and aesthetically pleasing glass applications.

3. Consistency and Reproducibility:

CNC edging eliminates the variability introduced by manual processes, ensuring that each piece of glass is consistent and reproducible. This is particularly crucial in industries where uniformity is a non-negotiable requirement.

4. Time and Cost Efficiency:

While the initial investment in CNC machinery may be significant, the long-term benefits include increased efficiency and reduced labor costs. The speed and accuracy of CNC edging contribute to faster production cycles and lower operational expenses.

5. Reduced Material Waste:

Precision CNC edging minimizes material waste by ensuring that each piece of glass is cut and finished accurately. This not only contributes to cost savings but also aligns with sustainability goals in reducing environmental impact.

Applications of CNC Edging:

1. Architectural Glass:

In the realm of architecture, CNC-edged glass has become a staple for high-end projects. The technology allows for the creation of custom edge profiles, beveled edges, and decorative patterns, contributing to the overall visual appeal of buildings.

Read more:

2. Automotive Industry:

The automotive sector benefits from CNC edging in the production of precision-cut glass components. Whether for windshields, side windows, or rear-view mirrors, CNC machines ensure that the edges meet the strict specifications required for safety and design.

Read more:

3. Electronics and Displays:

In the electronics industry, CNC-edged glass is vital for creating screens and displays with flawless edges. The precise machining allows for tight tolerances, contributing to the overall quality and performance of electronic devices.

Future Trends and Innovations:

As technology continues to advance, the future of CNC edging holds exciting possibilities. Integrating artificial intelligence for even smarter machining, exploring new materials, and further enhancing automation are just a few areas where innovation is expected to flourish.

CNC edging has undeniably transformed the glass fabrication landscape, setting new standards for precision and customization. As industries continue to demand higher quality and unique design solutions, the role of CNC edging in shaping the future of glass applications remains paramount. This sophisticated technology is not just a tool for manufacturers; it’s a testament to the limitless potential of merging craftsmanship with cutting-edge automation.

Want more information on CNC Edging? Techni-Glass can help with your project up to 62” x 129” in size. Get Started by sending your questions below!